Contents

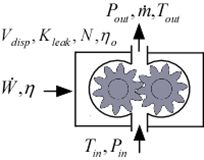

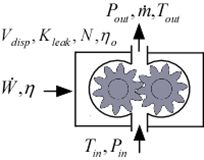

GearPump1_CL

This procedure provides a simple model of a gear pump. The volumetric flow rate is determined from displacement rate less leakage flow. Power is determined from overall efficiency applied to displacement flow rate. The parameters V_disp, K_leak, and eta_o can be obtained from manufacturer's performance data.

Inputs:

F$: fluid string identifier

C: concentration (%) {applicable when F$ is a brine. Otherwise set C=0.}

T_in: inlet temperature (K, C, F, or R)

P_in: inlet pressure (bar, atm, Pa, kPa, MPa)

P_out: outlet pressure (bar, atm, Pa, kPa, MPa)

N: rotational speed (1/s)

V_disp: displacement of pump per cycle (in^3 or m^3)

K_leak: leakage constant (in^2 or m^2); if K_leak<0, then a typical value will be used

eta_o: overall efficiency of pump (-)

Outputs:

m_dot: mass flow rate (kg/s or lb_m/hr)

T_out: outlet temperature (K, C, F, or R)

W_dot: power (W, kW or Btu/hr)

eta_p: actual efficiency relative to power

eta_v: volumetric efficiency

Example 1:

$UnitSystem SI Mass kJ C kPa

T_in=25 [C]

P_in=100 [kPa]

P_out=500 [kPa]

F$='DowTherm_J'

N=1700 [1/min]*convert(1/min,1/s)

V_disp=0.06 [liter]*convert(liter,m^3)

K_leak=3 [mm^2]*Convert(mm^2,m^2)

eta_o=0.6 [-]

Call GearPump1_CL( F$, C, T_in, P_in, P_out, N, V_disp, K_leak, eta_o: m_dot, T_out, W_dot, eta_p, eta_v)

{Solution:

eta_p=0.5773

eta_v=0.9621

m_dot=1.418 [kg/s]

T_out=25.18 [C]

W_dot=1.133 [kW]}

Example 2:

$UnitSystem SI Mass kJ C kPa

T_in=25 [C]

P_in=100 [kPa]

P_out=500 [kPa]

F$='EG' {ethylene glycol - water solution}

C=20 [%]

N=1700 [1/min]*convert(1/min,1/s)

V_disp=0.06 [liter]*convert(liter,m^3)

K_leak=3 [mm^2]*Convert(mm^2,m^2)

eta_o=0.6 [-]

Call GearPump1_CL( F$, C, T_in, P_in, P_out, N, V_disp, K_leak, eta_o: m_dot, T_out, W_dot, eta_p, eta_v)

{Solution:

eta_p=0.5773

eta_v=0.9651

m_dot=1.677 [kg/s]

T_out=25.17 [C]

W_dot=1.133 [kW]}

See also: GearPump2_CL

Index